Case Study

How to reduce water content in industrial recovered oil and slops using a skimming system

Background:

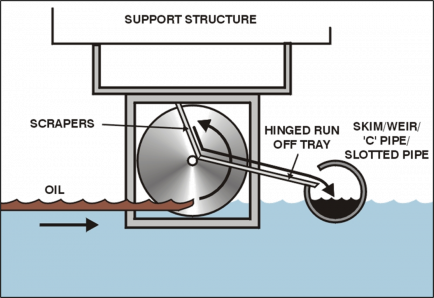

Vikoma’s T9 disc skimming system reduced water content in slops in an API type separator in a refinery, which halved the disposal costs of the slops. An automated system was provided with significant savings on manpower, compared to their previous skim pipe (C-pipe) solution.

Single bay API type separator in a distribution area of a specialist product refinery.

Feedstock - High viscosity crude oil.

Oil on separator - Hydraulic, lube oil, diesel & crude.

Separator area - No operator access without gas safety checks.

Classification - Zone 1.

Problem - Existing skim pipe recovery method (C-pipe) collected large quantities of water in the slops. It also required manual input to operate the skim pipe, which required operator’s access to a hazardous area.

Objective:

Customer objective 1: Reduce water content of slops.

Feedback: Slops water content significantly reduced by over 50%, reducing cost of disposal.

_____

Customer objective 2: Skimmer to discharge recovered oil, under gravity, into existing skim pipe and discharge pipework.

Feedback: Recovered oil discharged via a run off tray into the existing skim pipe.

_____

Customer objective 3: Skimmer to be capable of dealing with varying oil types and quantities.

Feedback: Skimmer picking up varying types and quantities of oil from the separator.

_____

Customer objective 4: Reduced manual input for health & safety as well as economic reasons.

Feedback: Skimmer is operating automatically and no manual input is required other than occasional visual check resulting in manpower cost savings.

_____

Customer objective 5: System to be automatic and requires only annual maintenance check.

Feedback: System operating for many years with no manual input other than annual maintenance.

Solution:

Vikoma installed a single fixed T9 skimmer module located in the API separator on a beam structure. The oil was recovered by the rotating T discs and discharged, under gravity, via a hinged run off tray into the existing skim pipe.

Explore Our Product Range

Oil Spill Solutions

Industrial Oily Water Skimming

Environment Protection

Areas in which we operate

News

Read the latest news article providing insight into our industry. You can also access all of our newsletters and sign up to future ones.

Case Studies

Vikoma have equipment case studies that that cover all areas of the spill response and Industrial oily water treatment industries.

History

Vikoma prides itself of having a dedicated team of employees with a combined experience and industry knowledge of over 100 years.

Can We Help You?

Contact Us