Case Study

How do I improve oil recovery efficiency in a separator or interceptor?

Background:

Our customer operates an oil refinery with two bay API type seperators. These had skim pipes installed however these were inefficient and flooded in high rainfall and the customer neded to reduce operator headcount. The Vikoma T14 oil skimming systems replaced the skim pipes and as it is an automatic system with very little manual input, enabled a headcount reduction. Varying liquid levels were overcome with a floating system which typically collects 2000 tonnes per annum with less than 2% water content.

Feedstock - Oil/water stream, mainly from crude oil storage areas plus some process plant cleaning water.

Oil on separator - Product and crude, approx. 50cSt viscosity.

Separator area - Zone 1.

Problem - Oil quantities very variable. The skim pipes flood during high rainfall, usually large liquid variations in the API separator as well as extremely high water content in the slops. Reduced operator availability.

Objective:

Customer objective 1: Continuous operation with minimal operator input.

Feedback: Skimmer is operating automatically and no manual input.

_____

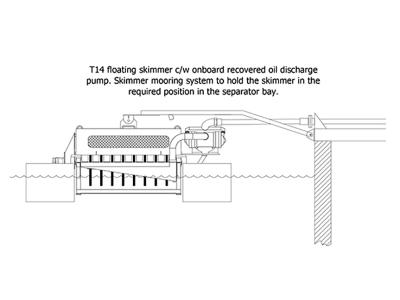

Customer objective 2: Floating skimmers c/w on-board pumps required in order to cope with liquid level variations.

Feedback: 2 T14 floating oil skimmers c/e on-board pumps installed.

_____

Customer objective 3: Low parts per million (PPM) level required in the discharge from the separator to secondary treatment.

Feedback: Recovered oil with <2% free water content (98% oil) achieved.

_____

Customer objective 4: Maximum biannual maintenance checks.

Feedback: Biannual maintenance checks, skimmers operating for many years with minimal down time for maintenance.

_____

Customer objective 5: Skimmer mooring system required in order to keep the floating skimmer in position.

Feedback: Skimmer fitted with stainless steel mooring arms in order to keep them in the required position in the separator bays.

_____

Customer objective 6: Fast removal of all surface oil required.

Feedback: Continuous oil removal with typical annual recovery of over 2000 tonnes.

Solution:

Vikoma installed two T14 floating skimmers c/w fixed mooring system, one in each bay of the API separator.

Explore Our Product Range

Oil Spill Solutions

Industrial Oily Water Skimming

Environment Protection

Areas in which we operate

News

Read the latest news article providing insight into our industry. You can also access all of our newsletters and sign up to future ones.

Case Studies

Vikoma have equipment case studies that that cover all areas of the spill response and Industrial oily water treatment industries.

History

Vikoma prides itself of having a dedicated team of employees with a combined experience and industry knowledge of over 100 years.

Can We Help You?

Contact Us