Case Study

How to separate the oil from oily water and slops using a skimming system?

Background:

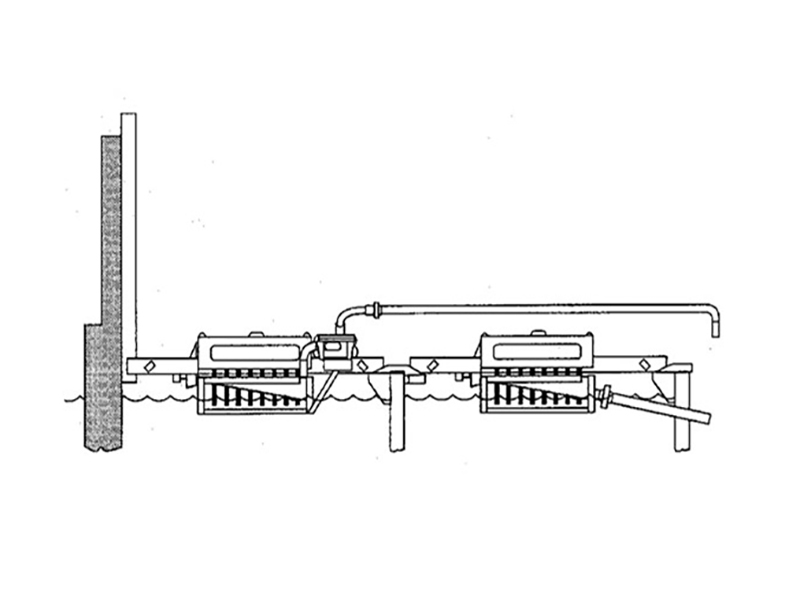

Two Vikoma T14 fixed, disc skimmers with on-board pumps were installed in each bay of an API separator in a refinery. Vikoma’s T14 disc skimming system increased the oil content of the slops to over 80% from the 20% typically achieved when using the conventional skim pipe solution. A skim pipe in a hazardous area needed significant manual intervention and so was replaced by Vikoma’s automated, continuous oil skimming system, significantly reducing the risk of personnel working in a hazardous area. The refinery API separator discharges were required to be a maximum of 15ppm for the efficient operation of the next treatment stage which was a dissolved air floatation system (DAF) and the Vikoma Skimmers were found to produce excellent results, well within the requirement.

Scenario - Four bay API type separator in an oil refinery.

Feedstock - Oil/water from many different sources including crude and product storage areas.

Oil on separator - Weathered crude oils, lube oil and light products.

Solvents - Occasional benzene and ethyl benzene.

Separator area - No operator access without gas safety checks

Classification - Zone 1

Objective:

Customer objective 1: Fixed skimmer systems c/w on-board pumps required.

Feedback : Two fixed T14 skimmers installed in each API separator bay.

_____

Customer objective 2 : Recovered oil ratio of minimum 80% oil and 20% water required.

Feedback : Typical recovered oil ratio achieved greater than 95% oil and 5% water.

_____

Customer objective 3 : Max 15ppm discharge from API separator for efficient DAF system.

Feedback : Typical discharge level from API of 2ppm achieved.

_____

Customer objective 4 : Continuous oil skimming required with minimal operator input.

Feedback : Skimmer is operating automatically and no manual input.

Solution:

Vikoma installed two x T14 fixed oil skimming systems with on-board pumps. Two skimmers fitted to a beam support frame in each of the API bays. A total of 8 skimming systems were provided.

Explore Our Product Range

Oil Spill Solutions

Industrial Oily Water Skimming

Environment Protection

Areas in which we operate

News

Read the latest news article providing insight into our industry. You can also access all of our newsletters and sign up to future ones.

Case Studies

Vikoma have equipment case studies that that cover all areas of the spill response and Industrial oily water treatment industries.

History

Vikoma prides itself of having a dedicated team of employees with a combined experience and industry knowledge of over 100 years.

Can We Help You?

Contact Us