Case Study

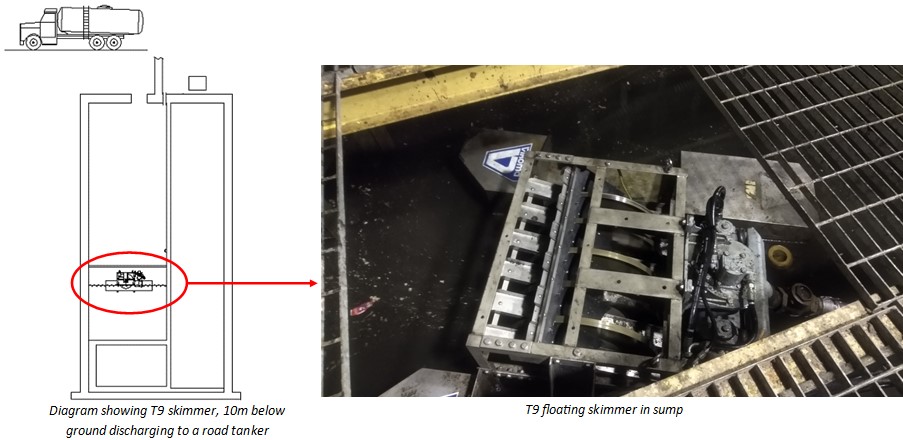

Can a skimmer be installed in a waste water sump under a highway?

Background:

In an area of heavy traffic there is a risk of oil, diesel and fuels from general traffic and accidents getting into the drainage system and polluting run off water. To prevent this pollution, a Vikoma skimmer was installed in a sump, 10m below ground level to collect oil and discharge to a road tanker. With a high oil content (98%), the volume of liquid collected is kept to a minimum, keeping road tanker costs much lower than other solutions where significantly more water is collected by the tanker.

Oil on sump - Lude oils, hydraulic oil and Naphtha.

Sump area classification - Zone 2.

Problem - The drainage sump is located 10m below ground level and there is a large volume of traffic in the area and this leads to a risk of spillage, diesel and oil etc. polluting run off water.

Objective:

Customer objective 1: The recovered oil must be able to be pumped directly to a road tanker for disposal.

Feedback: Skimmer system designed so that the recovered oil can be discharged directly into a road tanker.

_____

Customer objective 2: The skimmer must have a high recovery capability in case of a major spill.

Feedback: Skimmer capacity of over 9m3/hr.

_____

Customer objective 3: The recovered oil must have a minimal water content.

Feedback: 98% oil with typically 2% water achievable.

_____

Customer objective 4: The skimmer must operate safely and reliably within the confined space of the sump in the presence of hydrocarbon vapours.

Feedback: Skimmer certified to zone 2 for hazardous operating areas.

_____

Customer objective 5: The skimmer must pass through a 600mm x 750mm access hatch to the sump.

Feedback: A modular skimmer was designed capable of being dismantled and put in teh sump and reassembled.

Solution:

Vikoma installed a T9 floating oil skimmer system located in a sump 10m below ground. The skimmer was powered by a electro-hydraulic powerpack unit. The recovered liquid, with 98% oil content is discharged to a road tanker.

Explore Our Product Range

Oil Spill Solutions

Industrial Oily Water Skimming

Environment Protection

Areas in which we operate

News

Read the latest news article providing insight into our industry. You can also access all of our newsletters and sign up to future ones.

Case Studies

Vikoma have equipment case studies that that cover all areas of the spill response and Industrial oily water treatment industries.

History

Vikoma prides itself of having a dedicated team of employees with a combined experience and industry knowledge of over 100 years.

Can We Help You?

Contact Us